11.04.19

8:00-12:00 Practice Management, Project Development and Documentation

- Staff meeting, Project Reviews

- Ask questions about box project before Tuesday night

- 62945 – 1001 Middle St. Maint model

11.05.19

8:00-12:00 Project Development and Documentation, Construction and Evaluation

- CNC acrylic for truss template

- 62945 – 1001 Middle St. Maint model

11.06.19

8:00-12:00 Project Planning and Design

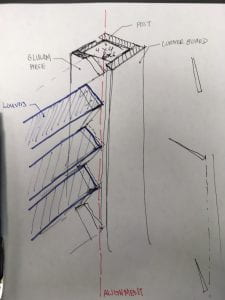

- Benjamin Mays – steeple detailing and model

- Circular Congregational Church Courtyard – intro and familiarize drawings

11.07.19

8:00-12:15 Project Planning and Design

- Circular Congregational Church Courtyard – ADA code assessment and adjustments

Week Reflection

- Enston Home Truss CNC

- To make building our structure in studio simpler, I had previously drawn CAD templates of our truss segments. These pieces were cut out of acrylic on the CNC this week. These templates will help make sure we can pattern shape our segments as well as align our bolt holes so that our assembly can go together smoother and stay aligned. Having never used or watched a CNC work, it was interesting to do. As always, there is an “order of operations” in setting the material, vacuuming it down so it is held in place, setting “layers” so that etching happens first, then inner cuts, then outer cuts. This helps make sure that there is minimal to no shifting so that no pieces crack. We ran into the problem of a smaller piece near the edge cracking, causing it to be recut twice. This took up more material and subsequently caused us to have to shift some of the other pieces (that also had a crack in them) around. We were successfully able to cut all the pieces of two sheets of acrylic. But it is a lesson learned in thinking about your placement of pieces on the bed and the order of cuts.